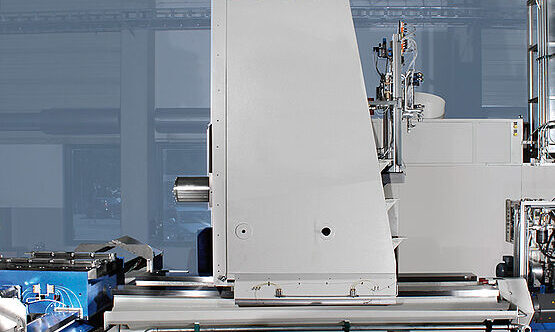

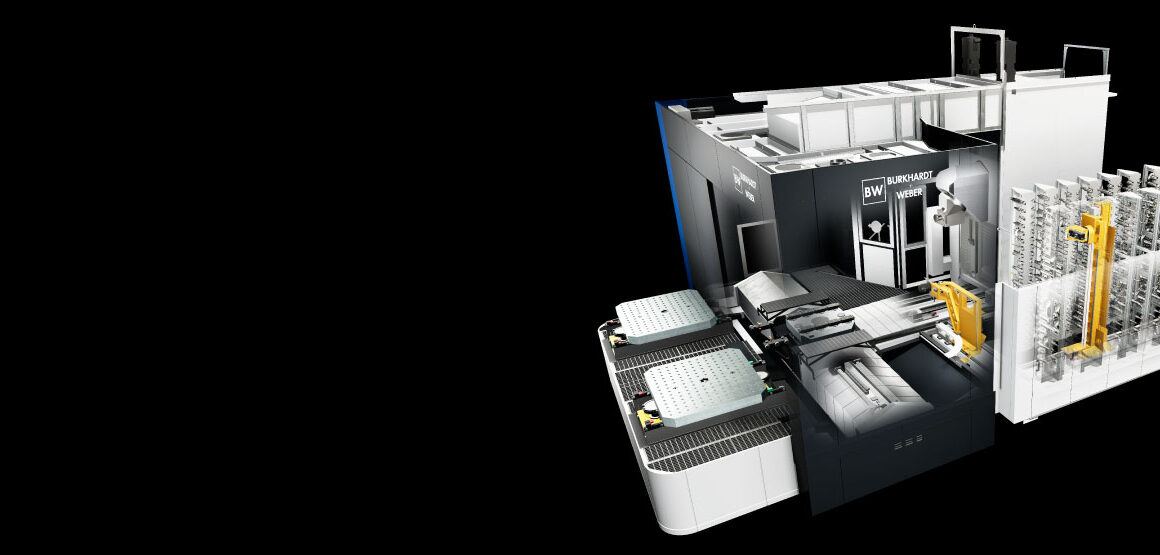

SLIDE-GUIDED MACHINING CENTERS.

The perfect solution for all applications calling for heavy-duty cutting with optimum damping characteristics, coupled with high-precision fine machining. BW offers seven different types with 1,500 to 3,500 mm (option 4,800 mm) workpiece swing diameter and 1,500 to 20,000 kg payload.

Pure power for difficult machining tasks.

MCR machining centers are very robustly dimensioned and feature high-performance spindle units. In addition to the cast-iron gantry column, extra-wide laser-hardened sliding guides guarantee optimum damping characteristics during machining of difficult materials as well as very high long-term precision due to extremely low surface pressures.

Technical Data - Metric System

| Technical Data | Unit | MCR 800 | MCR 900 | MCR 1000 | MCR 1100 | MCR 1200 | MCR 1400 | MCR 1600 |

|---|---|---|---|---|---|---|---|---|

| Working range (X | Y | Z ) | mm | 1,250 | 900 | 1,250 | 1,600 | 1,250 | 1,250 | 2.200 | 1.250 | 1.250 | 1,600 | 1,250 | 1,250 | 2,500 | 1,800 | 1,800 | 3,200 | 1,800 | 1,800 | 3,700 | 2,200 | 2,100 |

| Working range (X | Y | Z ) | mm | 1,250 | 900 | 1,600 | 1,600 | 1,250 | 1,250 | 2,400 | 1,500 | 1,600 | 1,600 | 1,500 | 1,600 | 2,800 | 2,200 | 2,100 | 3,500 | 2,200 | 2,100 | 4.100 | 2.200 | 2.100 |

| Workpiece swing diameter, Ø x H | mm | 1,500 x 1,300 | 1,700 x 1,750 | 2,300 x 1,900 | 1,600 x 1,750 | 2,800 x 2,100 | 3,200 x 2,300 | 3,700 x 2,600 |

| Pallet size, Standard 1 | mm | 800 x 800 | 800 x 1,000 | 1,000 x 1,250 | 800 x 1,000 | 1,000 x 1,250 | 1,600 x 1,600 | 2,000 x 2,000 |

| Pallet load(Opt.) | kg | 2,500 | 3,500 | 5,000 | 4,000 | 7,000 | 12,000 (14,000) | 20,000 |

| Rapid traverse, standard axis travel | m/min | 30 | 30 | 30 | 30 | 30 | 30 | 20 | 30 | 30 | 30 | 30 | 30 | 20 | 20 | 20 | 30 | 20 | 20 | 30 | 20 | 20 |

| Spindle power 100% duty rating | kW | 41 | 41 | 41 | 52 | 41 (60) | 41 (60) | 41 (60) |

| Torque 100% duty rating | Nm | 1.220 | 1.220 | 1.220 | 1.720 | 1.220 (3.500) | 1.220 (3.500) | 1.220 (3.500) |

| Speed range 2 gear steps | min-1 | 20-5.500 (10.000) | 20-5.500 (10.000) | 20-5.500 (10.000) | 20-5.500 (10.000) | 20-5.500 (10.000) | 20-5.500 (10.000) | 20-5.500 (10.000) |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | kg | 60 (75) | 60 (75) | 60 (75) | 60 (75) | 60 (75) | 60 (75) | 60 (75) |

Technical specifications are subject to change without prior notice.

Technical Data - Imperial System

| Technical Data | Unit | MCR 800 | MCR 900 | MCR 1000 | MCR 1100 | MCR 1200 | MCR 1400 | MCR 1600 |

|---|---|---|---|---|---|---|---|---|

| Working range | in | 49.21 | 35.43 | 49.21 | 63.00 | 49.21 | 49.21 | 86.61 | 49.21 | 49.21 | 63.00 | 49.21 | 49.21 | 94.49 | 70.87 | 70.87 | 126.00 | 70.87 | 70.87 | 138.80 | 86.61 | 82.68 |

| Working range optional | in | 49.21 | 35.43 | 63.00 | 63.00 | 59.10 | 63.00 | 94.49 | 59.10 | 63.00 | 63.00 | 59.10 | 63.00 | 110.24 | 86.61 | 82.68 | 137.80 | 86.61 | 82.68 | 137.80 | 86.61 | 82.68 |

| Workpiece swing diameter, Ø x H | in | 59.10 x 51.18 | 66.90 x 68.90 | 86.61 x 74.80 | 66.93 x 68.90 | 110.24 x 82.68 | 162.00 x 90.55 | 137.80 x 102.36 |

| Pallet size, standard 1 | in | 31.50 x 31.50 | 31.50 x 39.37 | 39.37 x 49.21 | 31.50 x 39.37 | 39.37 x 49.21 | 63.00 x 63.00 | 78.74 x 78.74 |

| Pallet load (opt.) | lbs | 5,512 | 7,716 | 11,023 | 8,818 | 15,432 | 26,455 | 44,092 |

| Rapid traverse, standard axis travel | in/min | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 787 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 787 | 787 | 787 | 1,181 | 787 | 787 | 1,181 | 787 | 787 |

| Spindle power 100% duty rating | HP | 55 | 55 | 55 | 55 | 55 (80) | 55 (80) | 55 (80) |

| Torque 100% duty rating | lb/in | 10,798 | 10,798 | 10,798 | 10,798 | 10,798 | 10,798 | 10,798 |

| Speed range 2 gear steps | min-1 | 20-5,500 (10,000) | 20-5,500 (10,000) | 20-5,500 (10,000) | 20-5,500 (10,000) | 20-5,500 (10,000) | 20-5,500 (10,000) | 20-5,500 (10,000) |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | lbs | 132.3 (165.3 | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) |

Technical specifications are subject to change without prior notic

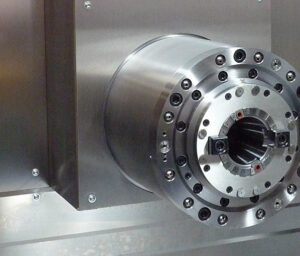

Extra-wide sliding guides.

The particularly large guide length and width of the thermally inert cast-iron gantry column guarantee high stability, even when machining in high spindle positions..

- Made by BURKHARDT+WEBER.

- Powerful and robustly dimensioned.

- Strictest quality controls.

- 24-hour load spectrum on BW test stand with programmable counter-loads.

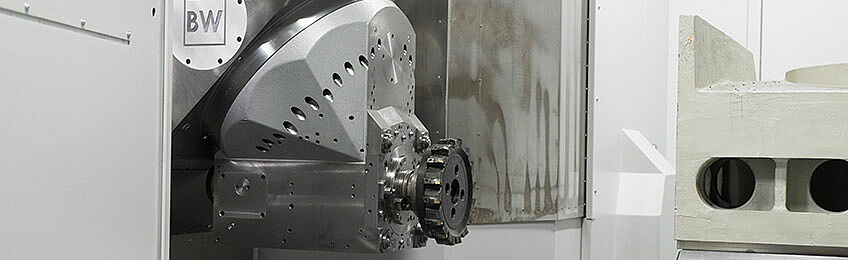

2-STAGE HORIZONTAL.

- Powerful gear spindles, up to 52 kW and 2,000 Nm.

- Up to 10,000 rpm for state-of-the-art tools.

4-STAGE HORIZONTAL.

- Powerful gear spindles for heavy machining, up to 80 kW, 3,600 Nm.

- Generously dimensioned bearings with large support span and speeds up to 5,000 rpm.

5-AXIS SWIVEL HEAD.

- NC-controlled, two gears.

- Up to 42 kW, 2,000 Nm, 8,000 rpm.

- 5-axis simultaneous machining.

- Generously-dimensioned bearing and high holding torque.

4-Stage Horizontal.

5-Axis-Swivel Head.

2-Stage horizontal.

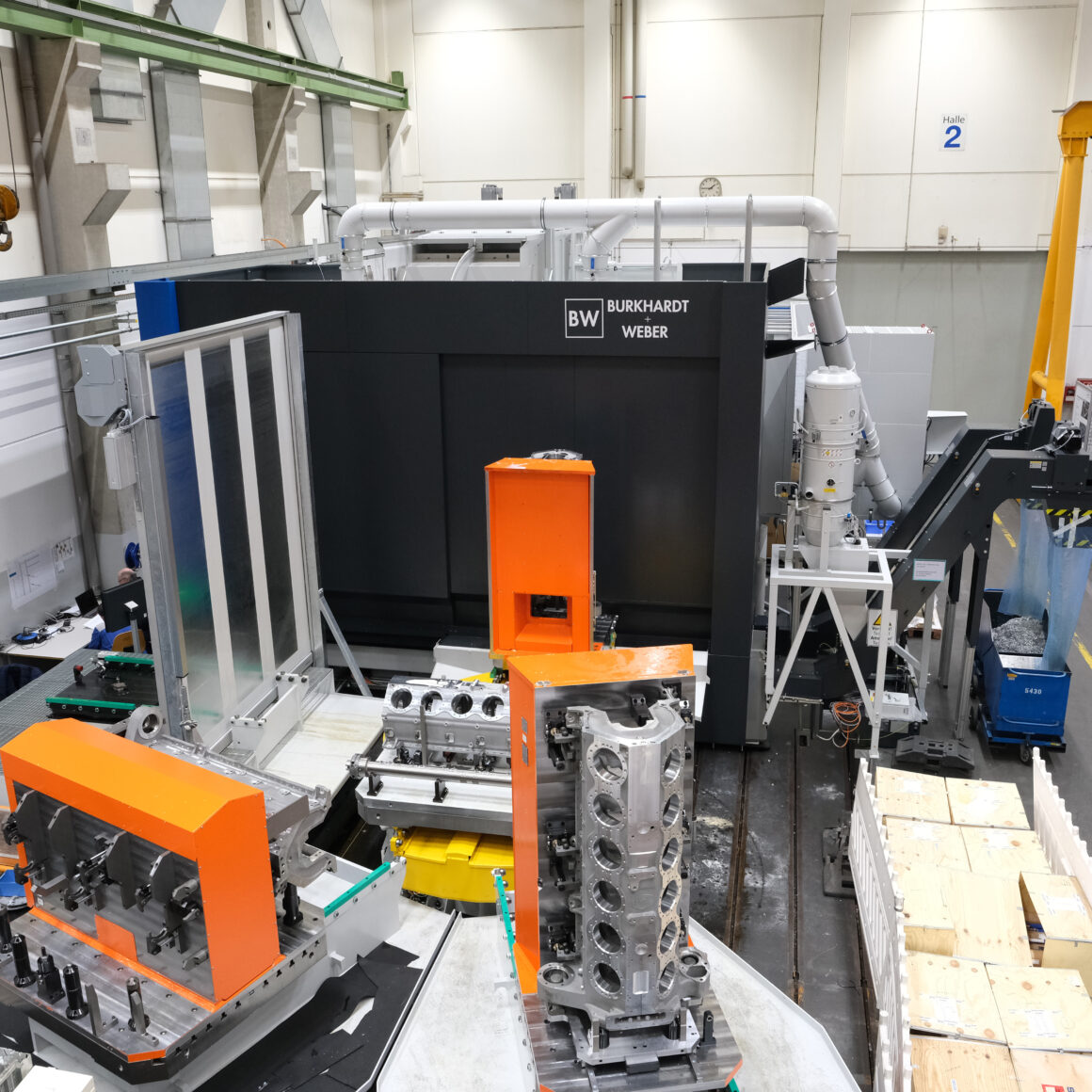

MACHINE TABLES AND PALLETS.

- Made by BURKHARDT+WEBER.

- Pallet loads from 1,500 kg to 20,000 kg.

- Particularly high tilting and tangential moments due to low table design and generously dimensioned axial roller bearings and holding brakes for optimum machining performance and excellent geometric results.

- For pallet loads over 12,000 kg, all tables have hydrostatic axial and radial bearings.

FACE PLATES.

- Face plates fitted vertically on the machine table.

- Optimum chip clearance and easy access when using short tools

- With a 5th NC-controlled axis

- Face plate diameter up to 2,000 mm

- Automatic switching from the pallet changer tooling station to the working area.

- Reliable and virtually wear-free thanks to cable-guided connection (no couplings).

- Face plate surfaces are freely configurable, because they are made in-house.

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 800 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1,200 mm.

- Boring bar diameters up to 900 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customized at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 22″ smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:

- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 800 locations for maximum flexibility.

We develop customer-specific solutions for special applications, such as automatic insertion equipment for very long series boring bar lengths up to 3,000 mm or 8 additional magazines for fast changeover of special tools weighing up to 500 kg each.

Tool gripper.

800 tool positions for maximum flexibility.

Special applications for customized solutions.

SMART PANEL: HIGH QUALITY 24“- FULL HD MULTI-TOUCH PANEL.

The machining centers are equipped with a high-quality 24″ multi-touch panel that leaves nothing to be desired. Innovative design, intuitive operation and straightforward user interface make the new panel another highlight of the BURKHARDT+WEBER machines. The pioneering panel allows the operator to quickly locate the desired functions, process parameters and supporting information.

- Smart panel: 24“ full HD multi-touch panel.

- Three independent display areas.

- Process data monitoring.

- Camera image.

- PDF-Viewer.

- Virtual keyboard.

- Easy-care, high-quality glass surface.

- High-quality aluminium housing.

- Machine control panel.

- Short-stroke keys with very good tactile feedback.

- Separate correction switch.

- Spindle speed.

- Feed rate.

- Rapid traversing speed.

- Keypad for customer-specific additional functions.

- Pivoted, height-adjustable mounting.

INTERFACE.

- Intuitive and quick operation.

- New and innovative display elements.

- Operator control of machine functions.

- Straightforward navigation.

- Process monitoring.

- Favourites list.

- Search function.

- Tool management operating area.

- Easier tool data entry.

- Graphic support.

- Automatic determination of the tool type.

- Straightforward and dynamic.

- Plausibility check.

- Clear separation of BW applications and Sinumerik Operate user interface for intuitive operation.

- Parallel and independent operation of the machine and tool magazine.

Smart Panel - SINUMERIK ONE.

Convenient operationg areas.

Flexible and unattended production.

PALLET CHANGER, STANDARD.

- Dual pallet changer; set up during machine operation.

- Load-dependent, servo-driven gates for rapid pallet changing.

THIRD AND FOURTH PALLET CHANGING STATION.

- Very economical in the case of multiple clamping locations or a third shift.

- Every tooling station can be set up autonomously.

CIRCULAR PALLET STORE.

- Rapid changeover with up to six pallets in the system.

- Motor-driven, rotating, generously dimensioned tooling station.

LINEAR LINKING SYSTEMS.

- Unmanned operation of multiple machining centres in BW’s own rail-guided linked system.

INTEGRATION IN MULTI-LEVEL SYSTEMS.

- Simple integration in modern high rack systems.

ROBOT LOADING.

- Automated workpiece handling.

- Intelligent, self-centring, hydraulic clamping devices.

Palett changing station.

Rotary Pallet Store.

Integration in high rack systems.

Robot loading.

Much of what you pay highly for from other companies serving the market comes as standard with BW machines..

ENERGY-EFFICIENCY.

OPERATOR ERGONOMICS.

WEEKEND CURCUIT.

WORKING AREA RINSING.

MAINTENANCE.