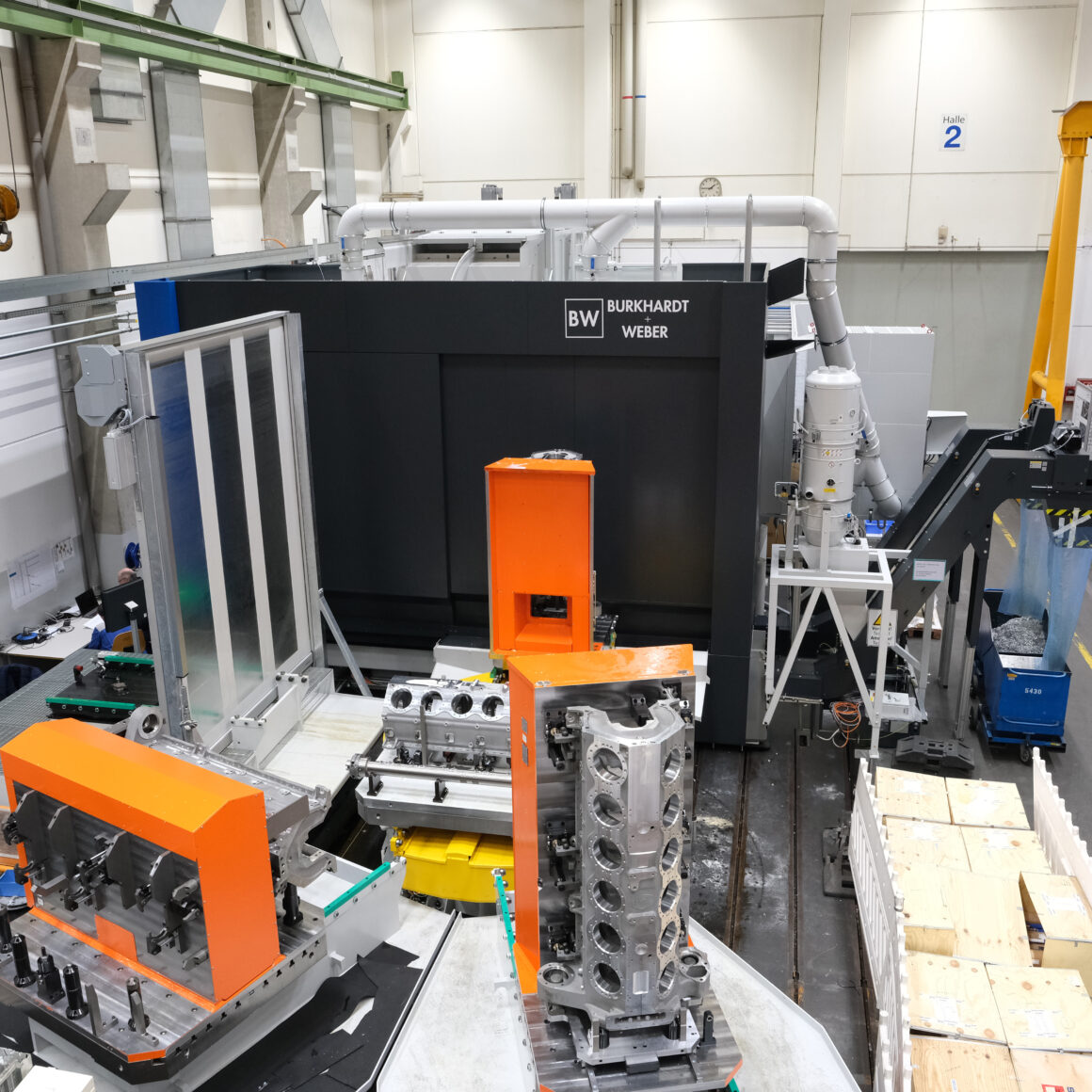

- Made by BURKHARDT+WEBER.

- Gearless and directly driven.

- Assembled by highly experienced employees.

- Strictest quality controls.

- 24-hour load spectrum on BW test stand with programmable counter-loads.

- Highest surface qualities demand the best possible concentricity and total absence of vibration. Consequently, BW only installs gearless spindle units in the MCµ, whose drive system operates decoupled from all vibration.

- With 610 Nm, 32 kW (S1) and speeds up to 6,000 rpm, cost-effective precision machining of all materials is guaranteed.

- The slim but nevertheless expansive spindle design allows loading of the spindle in house with short tools optimised for concentricity.

- The complete spindle cooling system with linear expansion compensation ensures stable length ratios in the process.

When accurate is not accurate enough.

Machines of the MCµ series are designed for ultimate precision and long-term accuracy. Close to µ accuracy and – as always at BW – not just on the day of commissioning, but over many years of use. The MCµ series is no standard machine trimmed for accuracy. The MCµ is based much more on a fundamentally new concept. Because the final µ is the result of many specific individual measures, such as careful design, best materials, strict production methods and very experienced employees. MCµ: Accuracy by design, not compensation.

The result is the most precise machine series we've ever built.

The MCµ provides tightest geometric tolerances (positioning, flatness, radial eccentricity, concentricity, angularity, repositioning) for the most demanding applications. The basis for long-term accuracy is maximum stability from the ground up. High guide bars, FEM-optimised structures cast from mineral casting material, a thermally inert system and active tempering are examples of the many measures taken. BW's very high degree of vertical integration in all core components is decisive for the successful implementation of such accurate machines.

Quality philosophy

The µ on the finished component depends on many factors: positioning accuracy, machine geometry, tool concentricity, fixture warpage, material characteristics, process sequence, temperature differential and measuring method. Consequently, every component of an MCµ is subject to the tightest tolerances and undergoes special quality assurance measures, just like the finished machine. Finally, comprehensive measurements are taken of every single MCµ.

Employee expertise

The key to successful production of an MCµ lies in the extremely high qualification level of our employees. We have been building high-precision machining centres successfully for almost 60 years now. Our philosophy, calling for continuous optimisation of every component and process, is practised every day in our committed team of perfectionists.

Cost-effectiveness

Cost pressure is leading to fewer and fewer clamping operations, which in turn leads to more complex components. This is significantly increasing the demands on machining, while rapidly reducing the joining component. The MCµ targets mounting rather than adjustment.

Customization

BURKHARDT+WEBER builds highly customised machining centres. The same applies unreservedly to the MCµ series. We have broad expertise in the production of high-precision components, not least due to the high degree of vertical integration with our own precision components, and from many customer projects.

Technical Data - Metric System

| Technical Data | Unit | MCµ 800 | MCµ 900 | MCµ 1000 | MCµ 1200 | MCµ 1250 |

|---|---|---|---|---|---|---|

| Working range | mm | 1,250 | 1,000 | 1,250 | 1,600 | 1,400 | 1,600 | 2,200 | 1,400 | 1,800 | 2,800 | 1,400 | 1,800 | 2,800 | 1,800 | 2,100 |

| Workpiece swing diameter, Ø x H | mm | 1,500 x 1,300 | 1,600 x 1,750 | 2,300 x 1,900 | 2,650 x 1,900 | 2,800 x 2,500 |

| Pallet size, standard | mm | 800 x 800 | 800 x 1,000 | 1000 x 1,250 | 1,000 x 1,250 | 1,000 x 1,250 |

| Pallet load | kg | 2,500 | 3,000 | 5,000 | 6,000 | 7,000 |

| Rapid traverse, standard axis travel | m/min | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Spindle power 100% duty rating | kW | 50 | 50 | 50 | 50 | 50 |

| Torque 100% duty rating | Nm | 250 | 250 | 250 | 250 | 250 |

| Speed range 2 gear steps | min-1 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | kg | 60 | 60 | 60 | 60 | 60 |

Technical specifications are subject to change without prior notice.

| Technical data | Unit | MCµ 800 | MCµ 900 | MCµ 1000 | MCµ 1200 | MCµ 1250 |

|---|---|---|---|---|---|---|

| Working range | in | 49.21 | 39.37 | 49.21 | 63.00 | 55.12 | 63.00 | 86.61 | 55.12 | 70.87 | 98.43 | 70.87 | 70.87 | 110.24 | 70.87 | 82.68 |

| Workpiece swing diameter, Ø x H | in | 59.06 x 51.18 | 63.00 x 68.90 | 90.55 x 74.80 | 98.43 x 82.68 | 110.24 x 98.43 |

| Pallet size, standard | in | 31.50 x 31.50 | 31.50 x 39.37 | 39.37 x 49.21 | 39.37 x 49.21 | 39.37 x 49.21 |

| Pallet load | lbs | 4,409 | 6,614 | 11,023 | 13,228 | 15,432 |

| Rapid traverse, standard axis travel | in/min | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 | 1,181 |

| Spindle power 100% duty rating | HP | 43 | 43 | 43 | 43 | 43 |

| Torque 100% duty rating | lb/in | 5,400 | 5,400 | 5,400 | 5,400 | 5,400 |

| Speed range 2 gear steps | min-1 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | lbs | 132.3 | 132.3 | 132.3 | 132.3 | 132.3 |

Technical specifications are subject to change without prior notice.

- Made by BURKHARDT+WEBER.

- Best axial eccentricity and maximum swing-in accuracy.

- Highly elaborate production of table housing and head plate.

- Precision bearings and worm gears of utmost quality.

- Extremely careful assembly with frequent coordination of dimensions.

- Guarantees virtually no axial eccentricity and tightest swing-in accuracies.

- Naturally, all table units of the MCµ series are designed in-house at BW.

- Production by our experienced specialists in-house.

- Comprehensively designed run-in tests and measurements are additional safeguards for high BW quality.

The modular, highly flexible tool magazines are peerless and market-leading worldwide.

- Made by BURKHARDT+WEBER.

- Maximum capacity of 800 tools.

- 5 highly dynamic NC axes.

- Traversing speeds up to 200 m/min.

- Changeable weight up to 60 kg, tilting moment up to 150 Nm.

- Tool lengths up to 1,200 mm.

- Boring bar diameters up to 600 mm.

- Automatic determination of the tool tilting moment and weight.

- Application-oriented pre-storage and comprehensive tool management for maximum convenience.

- Every magazine can be fully customized at the time of ordering and easily retrofitted or expanded, if required, even years later.

- Loading and unloading at a loading station with 2 x 8 locations operating in parallel with machining.

- Clever tool management and 21″ smart control panel (optional).

- Tool data transfer via chip, print code or online.

Versions:

- 128 locations in basic version for series production.

- 352 locations for machining workpiece families.

- 800 locations for maximum flexibility.

Tool Gripper.

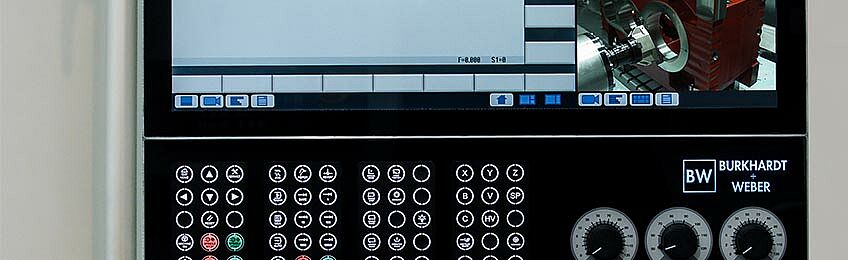

SMART PANEL: HIGH QUALITY 24“- FULL HD MULTI-TOUCH PANEL.

The machining centers are equipped with a high-quality 24″ multi-touch panel that leaves nothing to be desired. Innovative design, intuitive operation and straightforward user interface make the new panel another highlight of the BURKHARDT+WEBER machines. The pioneering panel allows the operator to quickly locate the desired functions, process parameters and supporting information.

- Smart panel: 24“ full HD multi-touch panel.

- Three independent display areas.

- Process data monitoring.

- Camera image.

- PDF-Viewer.

- Virtual keyboard.

- Easy-care, high-quality glass surface.

- High-quality aluminium housing.

- Machine control panel.

- Short-stroke keys with very good tactile feedback.

- Separate correction switch.

- Spindle speed.

- Feed rate.

- Rapid traversing speed.

- Keypad for customer-specific additional functions.

- Pivoted, height-adjustable mounting.

INTERFACE.

The user interface of the BURKHARDT+WEBER machining centers features innovative, machine-specific operating areas. These impress with their modern design and functionality. Enhanced user-friendliness was the focus of this new development. And this succeeded in impressive fashion through use of modern control elements and additional convenience functions. The intuitively operated areas making it easier for the operator to enter data, plan jobs and control the machine.

- Intuitive and quick operation.

- New and innovative display elements.

- Operator control of machine functions.

- Straightforward navigation.

- Process monitoring.

- Favourites list.

- Search function.

- Tool management operating area.

- Easier tool data entry.

- Graphic support.

- Automatic determination of the tool type.

- Straightforward and dynamic.

- Plausibility check.

- Clear separation of BW applications and Sinumerik Operate user interface for intuitive operation.

- Parallel and independent operation of the machine and tool magazine.

Intuitive Operation.

Machine-specific operating areas.

Flexible and unattended production.

PALLET CHANGER, STANDARD.

- Dual pallet changer; set up during machine operation.

- Load-dependent, servo-driven gates for rapid pallet changing.

CIRCULAR PALLET STORE.

- Made by BURKHARDT+WEBER.

- Rapid changeover with up to six pallets in the system.

- Motor-driven, rotating, generously dimensioned tooling station.

LINEAR LINKING SYSTEMS.

- Made by BURKHARDT+WEBER.

- Unmanned operation of multiple machining centres in rail-guided linked system.

INTEGRATION IN MULTI-LEVEL SYSTEMS.

- Simple integration in modern high rack systems.

- Turn key solutions.

ROBOT LOADING.

- Automated workpiece handling.

- Intelligent, self-centring, hydraulic clamping devices.

Integration in high rack systems.

Rotary pallet store.

ENERGY EFFICIENCY.

OPERATOR ERGONOMICS.

MAINTENANCE.