BW offers you numerous special solutions and equipment from its own production as well as customized designs to adapt your machining center even more closely to your individual production processes.

Your added value?

Reduced processing times and maximum quality. Together for more productivity. Your ideas lead to our designs, making your special machining center even more economical.

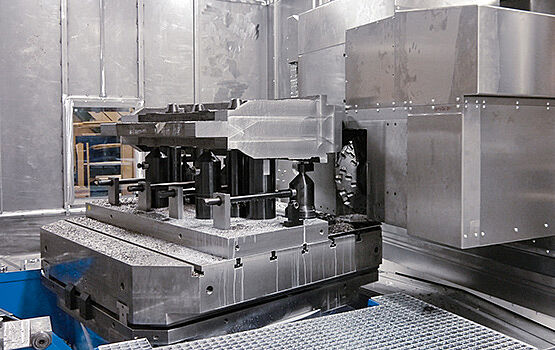

If the large machine magazines no longer suffice, there is a solution for this as well: a background magazine built from modules of the machine magazine with up to 3,000 tools and convenient magazine management.

Special heads for special tasks: fixed or adjustable angular heads, milling heads, sawing heads, gear cutting heads and multi-spindle drilling heads. Sleeves for automatic extension of large tools and associated feeding and changing equipment.

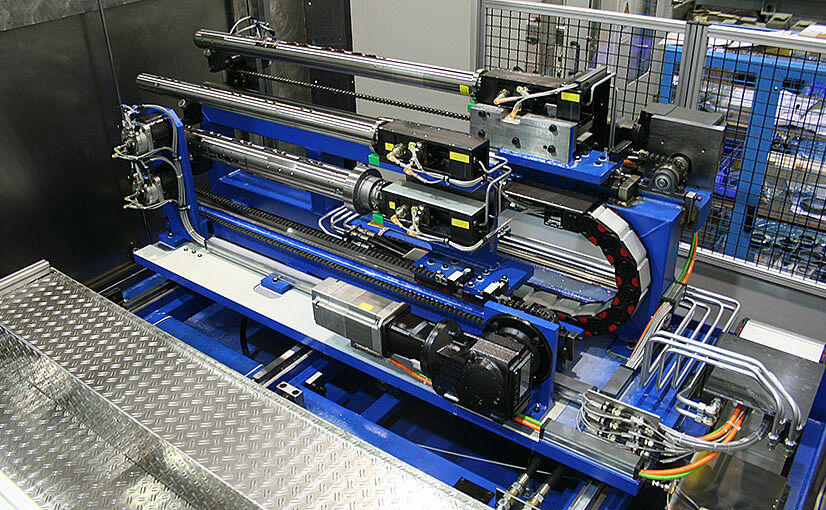

One or more boring bars with lengths up to 4,500 mm are not fed from the magazine, but by means of automatic feeding from an external station. Naturally, NC-controlled and from in-house production

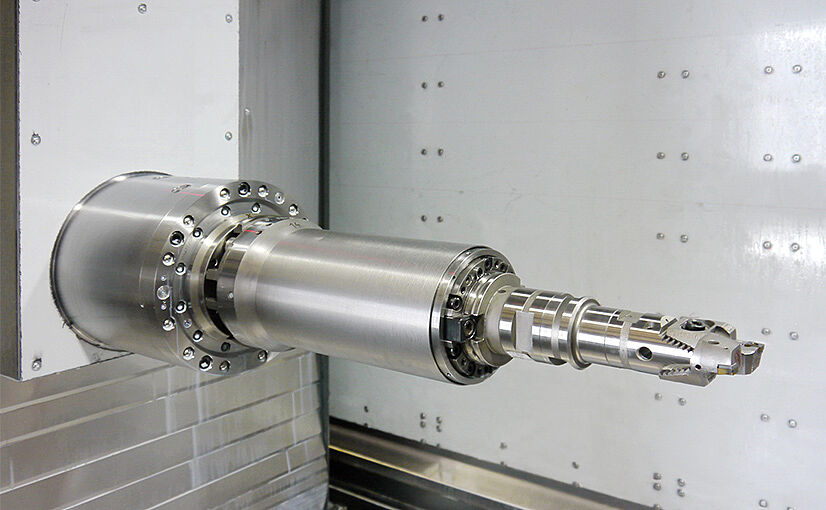

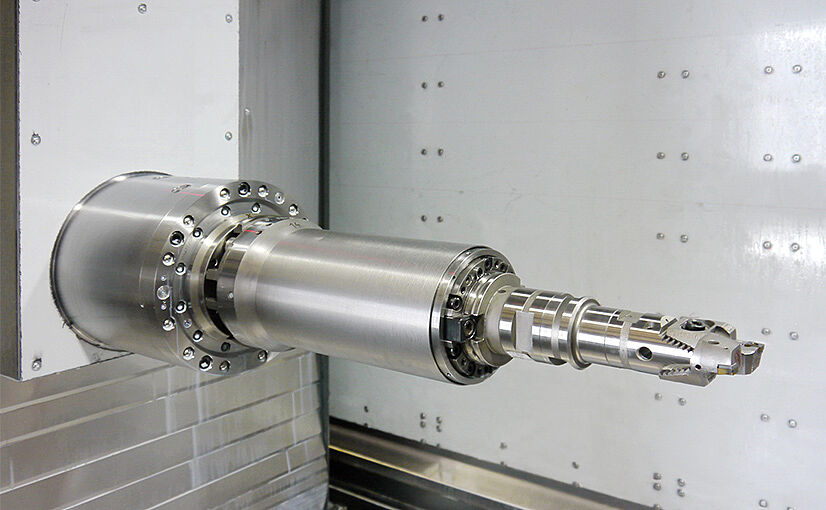

The original from its inventor. It can extend each tool weighing up to 40 kg automatically by 350 mm. Perfect concentricity, because no expensive intermediate adapters are required for boring bars or extensions. The integrated vibration absorber is effective against milling vibration.

BW offers quill spindle developed and produced in-house with extension lengths up to 1,000 mm and automatic sag compensation. We make the quill spindle insensitive to thermal expansion due to the machining environment through automatic length compensation by means of Invar inserts.

NC-controlled facing heads featuring slide-guided facing slides and controlled counterweight for imbalance reduction. BW’s own face-turning unit with control shaft in the centre of the tool adapter is NC-controlled and permits µ-accurate adjustments of the turning tool on the facing slide through the high transmission ratio in the facing head.

Fully integrated drilling head changer for storing two NC-controlled special heads with automatic tool change for up to 30 tools.

Vertically installed on the machine table, optimum chip clearance and easy access. Freely configurable surface. Face plate diameter up to 2,000 mm.

FLEXIBILITY – IN ALL DIMENSIONS

Almost all machine series of BURKHARDT+WEBER are available as 5-axis version including a HV-head, an A-axis (fork head) or a rotary/tilting table. The fields of application vary from aerospace industry to standard machine building as well as manufacturers of semiconductors and optical components.Gears up to a module of 9 can be produced with Power Skiving. Our solid and precise machining centres operate in single-item, small batch and serial part production. The A-axis is equipped with a motor spindle of 12.000 min-1 designed for particularly high speeds in continuous operation and optionally has a 4 point clamping for the adaption of turning tools. The spindle nose is pulled forward to avoid collision with the workpiece and to enable the machining of complex and diagonally arranged contours. In addition, the A-axis convinces with a high feed and clamping torque of the swivel axis. The fifth axis is applicable in different variations, either as continuous CNC-axis or as a plain positioning axis. The objective is to completely machine workpieces in a single clamping operation in order to meet the increasing demands for accuracy. Finally, this reduces the fixture costs and set-up times.

The BW custom-designed rotary/tilting table is always in action when the workpiece geometry makes is necessary.

The BURKHARDT+WEBER 5-axis multi-tasking machining centers enable a complete machining of workpieces with the technique of milling – turning – drilling.