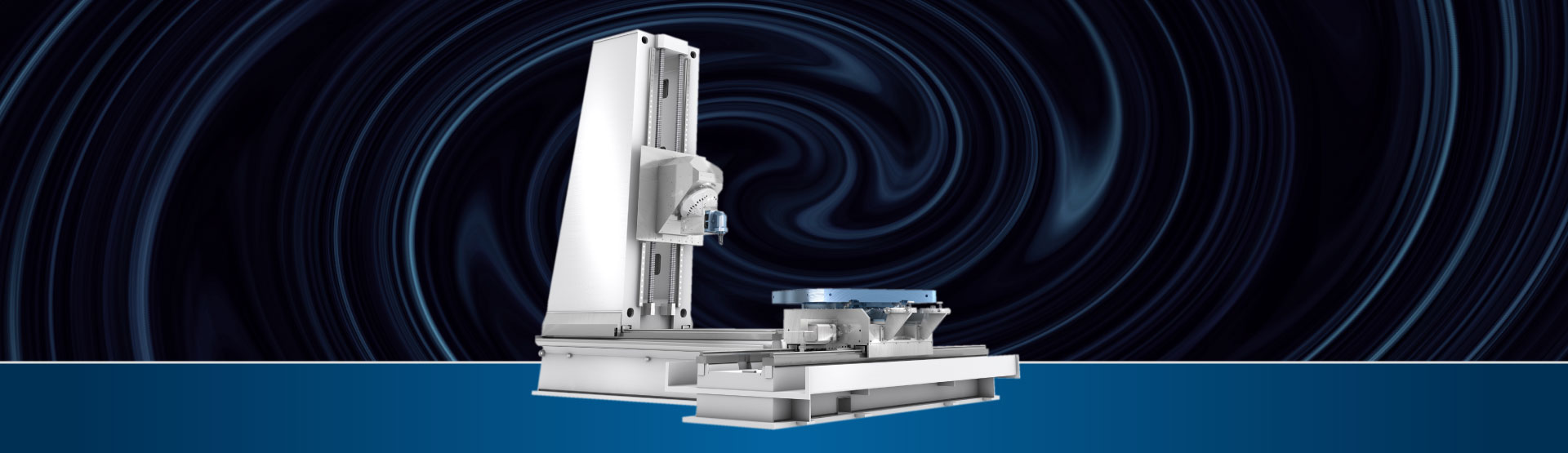

铣、钻和车削—MCT系列多任务复合加工中心

六款MCT系列加工中心设计特别适合于多任务复合加工的应用,集成于数控立卧转换摆动主轴,强力车刀架和快速车削扭矩转台,大功率铣削、钻削、车削所有加工工序一次完成。集立式车削和卧式车削功能于一身,可代替多台车床

通过柔性化实现高效加工

BW自制转台拥有强力撤销扭矩电机和超大规格铣削/钻削B轴刹车系统,适合钢件、铸铁件、高温合金等超硬材料的高效切削。所有BW机床功能选项均适配于MCT系列机床。MCT系列机床可与其他系列机床采用相同的托盘及交换系统,可以一起并入柔性加工线

Technical Data Metric system

| Technical data (Metric system) | MCT 800 | MCT 900 | MCT 1000 | MCT 1200 | MCT 1250 | |

|---|---|---|---|---|---|---|

| Working Range (X | Y | Z) | mm | 1,250 | 1,000 | 1,250 | 1,600 | 1,400 | 1,800 | 2,200 | 1,400 | 1,800 | 2,800 | 1,500 | 2,100 | 2,800 | 2,200 | 2,100 |

| Working range optional | mm | 1,400 | 1,200 | 1,500 | 1,800 | 1,500 | 1,800 | 2,200 | 1,500 | 1,800 | 2,800 | 1,500 | 2,100 | 2,800 | 2,200 | 2,500 |

| Workpiece swing diameter Ø x h | mm | 1,500 x 1,300 | 1,600 x 1,750 | 2,300 x 1,900 | 2,650 x 1,900 | 3,000 x 2,500 |

| Pallet size (Standard) | mm | 800 x 800 | 800 x 1,000 | 1,000 x 1,250 | 1,000 x 1,250 | 1,000 x 1,250 |

| Pallet load (turning) | kg | 2,500 (2,000) | 3,500 (2,500) | 5,000 (4,000) | 7,000 (4,000) | 7,000 (4,000) |

| Rapid traverse, axis travel (X | Y | Z ) | m/min | 65 | 65 | 65 | 65 | 65 | 65 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Spindle power, 100 % duty rating | kW | 41 | 41 | 41 | 41 | 41 |

| Torque 100 % duty rating | Nm | 1,400 | 1,400 | 1.400 | 1.400 | 1.400 |

| Speed range | min-1 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | kg | 60 (75) | 60 (75) | 60 (75) | 60 (75) | 60 (75) |

1 similar DIN 55201-A1/B1

Technical specifications are subject to change without prior notice.

Technical Data Imperial System

| Technical data | MCT 800 | MCT 900 | MCT 1000 | MCT 1200 | MCT 1250 | |

|---|---|---|---|---|---|---|

| Working range ( X | Y | Z ) | in | 49.21 | 39.37 | 49.21 | 63.00 | 55.12 | 70.87 | 86.61 | 55.12 | 70.87 | 98.43 | 70.87 | 82.68 | 110.24 | 86.61 | 82.68 |

| Working range optional ( X | Y | Z ) | in | 43.31 | 43.31 | 55.12 | 70.87 | 59.06 | 70.87 | 86.61 | 59.06 | 70.87 | 110.24 86.61 98.43 | 110.24 86.61 98.43 |

| Workpiece swing diameter, Ø x H | in | 59.06 x 51.18 | 63.00 x 68.90 | 90.55 x 74.80 | 98.43 x 82.86 | 110.24 x 98.43 |

| Pallet load (turning) | lbs | 5,512 (4,409) | 7,716 (5,512) | |||

| Rapid traverse, standard axis travel | in/min | 2,559 | 2,559 | 2,559 | 2,559 | 2,559 | 2,559 | 1,969 | 2,362 | 2,362 | 1,969 | 1,969 | 1,969 | 1,969 | 1,969 1,969 |

| Spindle power 100% duty rating | HP | 55 | 55 | 55 | 55 | 55 |

| Torque 100% duty rating | lb/in | 12,391 | 12,391 | 12,391 | 12,391 | 12,391 |

| Speed range 2 gear steps | min-1 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 | 20-8,000 |

| Number of tool pockets | 128-800 | 128-800 | 128-800 | 128-800 | 128-800 | |

| Tool weight | lbs | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) | 132.3 (165.3) |

1 similar DIN 55201-A1/B1

Technical specifications are subject to change without prior notice.

- BW制造

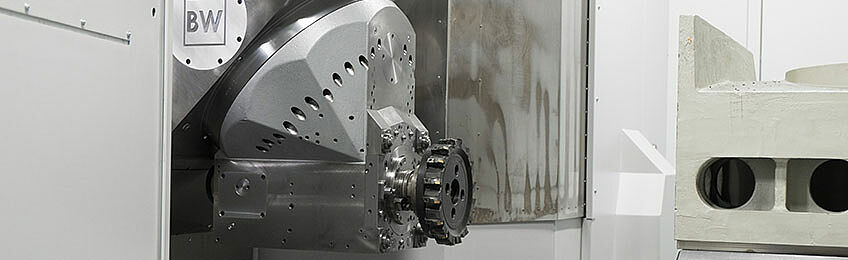

- 强力和宽大支撑的立卧转换主轴头

- 为了连接选配型车刀架,主轴头标配四点液压夹紧系统

- 资深员工进行装配

- 严苛的质量控制

- 在BW试验台进行24小时可编程负载测试

- 数控HVP任意角度定位主轴头或HVC 5轴联动摆动主轴头

- 最高转速达8,000 rpm,功率/扭矩 42 kW / 2,000 Nm,2级齿轮变速

- 立卧转换时间2秒

- 车刀自动从刀库交换到特殊车刀架上

- 车刀架具有主轴相适应的液压夹紧接口

- 车削过程中的车削力不会影响主轴轴承。所有力量均有四点液压夹紧套吸收,而且支撑带可对侧面力量的稳定吸收。

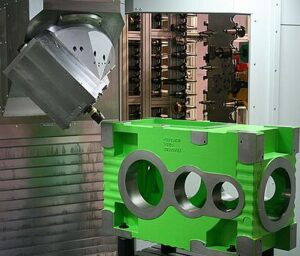

- 高速车削,高性能铣/车转台

- BW制造

- 转速达650 rpm

- 承重达7,000 kg,车削承重达 4,000 kg

- 自动平衡循环带不平衡量监控

- 显示配重位置和重量

- 通过大尺寸刹车盘进行铣削模式的稳定脱开,当液压夹紧时,没有任何位置转动

- 高性能,4边冷却的扭矩电机阻止单方向热膨胀

- 特殊托盘表面可订制,因为BW自制

- 选配液压接口

- 在BW专用试验台上进行质量和功能验收测试

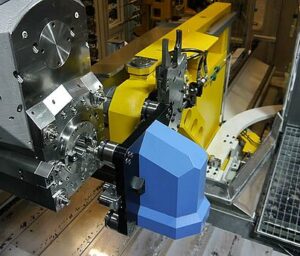

无与伦比的高度模块化柔性刀库,世界领先

- BW制造

- 最大刀库容量800把

- 5根数控轴,非常灵活

- 快移速度200m/min

- 最大刀具重量60kg,倾覆扭矩150Nm

- 最大刀具长度1,200mm

- 最大镗刀直径900mm

- 自动监控刀具重量和倾覆扭矩

- 基于具体应用的刀库配置和外围刀具管理,实现最大便利性

- 每个刀库均可在订货时进行客户化配置,使用多年后也便于拓展和重新构造

- 上下料站可同时进行2×8把刀具的装卸,并行于加工时间

- 聪明刀具管理和22″SMART操作面板(可选)

- 刀具参数传输可通过屑片、打印码和在线传输

版本:

- 容量128把标准版本,用于系列工件加工

- 容量352把用于多品种工件加工

- 容量800把用于最大柔性加工

我们开发客户化特殊方案,如镗杆长度达3,000 mm的自动交换单元或单个刀具重量达500 kg 的8个附加刀库。

All machining centers are equipped with the Siemens Sinumerik ONE control system.

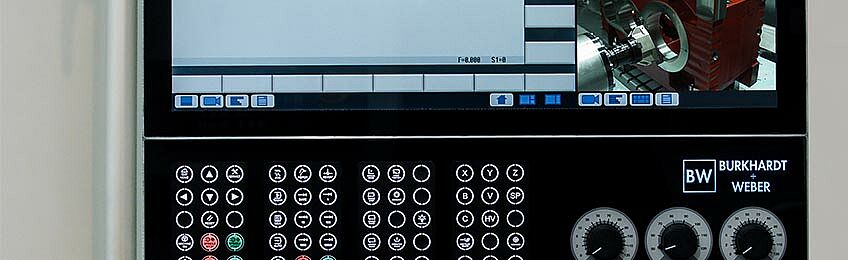

SMART操作面板: 高品质24“- 高分辨率多点触摸操作面板

- 24“ 高分辨率多点触摸屏操作面板

- 三个独立显示区

- 过程参数监控

- 影像区

- PDF编辑区

- 虚拟键盘区

- 容易护理的高品质玻璃面板

- 高品质铝合金框架

- 机床控制面板

- 短程按键,良好的触觉感受

- 独立修正开关

- 主轴速度

- 进给倍率

- 快移速度

- 客户化附加功能按键

- 旋转、高度可调整

便利操作区域.

- 直观和快捷操作

- 创新显示

- 机床控制操作功能

- 联机附加功能

- 便捷功能导航

- 过程控制

- 优先清单

- 搜索功能

- 刀具管理操作区

- 更加容易刀具参数输入

- 图形支持

- 刀具型号自动定义

- 数据自动执行

- 直接和灵活

- 可行性检查

Intuitive operation.

Convenient machine-specific operating area.

柔性化和无人化生产

托盘交换器,标准配置

- 双托盘交换,机床加工运行时设置

- 人工上下料,托盘快速交换伺服驱动

托盘池

- BW制造

- 该系统可以配置六个托盘自动交换

- 电机驱动,回转设计,大规格尺寸装卸站

线性多托盘系统

- BW制造

- BW轨道联机系统实现多台机床的无人化操作

并入高架系统

- 简单并入现代化高架系统

- 交钥匙方案

市场上其他公司的高昂选配项在BW机床上均为标配。

高效节能

人体工程学设计

周末循环功能

工作区域喷淋

维护