您的附加值?

缩短加工时间,提高质量。共同提高生产率。我们根据您的想法进行设计,使您的专用加工中心更具经济性。

如果大型刀库容量仍然不够用,可以提供基于刀库模块化设计的背置式刀库方案,容量达3,000把和具有便捷式刀库管理模式。

特殊加工任务需要特殊附件头,如固定式或可调整式角度头、铣头、锯片、齿轮切削附件头和多轴钻头。套筒用于大刀具的自动延伸、相应进给和交换装置。

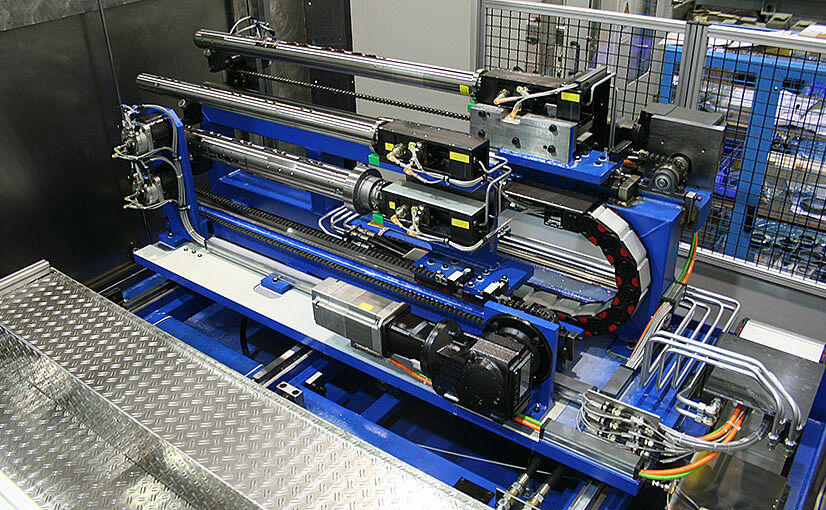

虽然一个或多个线镗长度超过4,500mm后不能自动存储在标准刀库中,但是可以从外围附加刀库站进行自动进给。数控方式和BW研发制造。

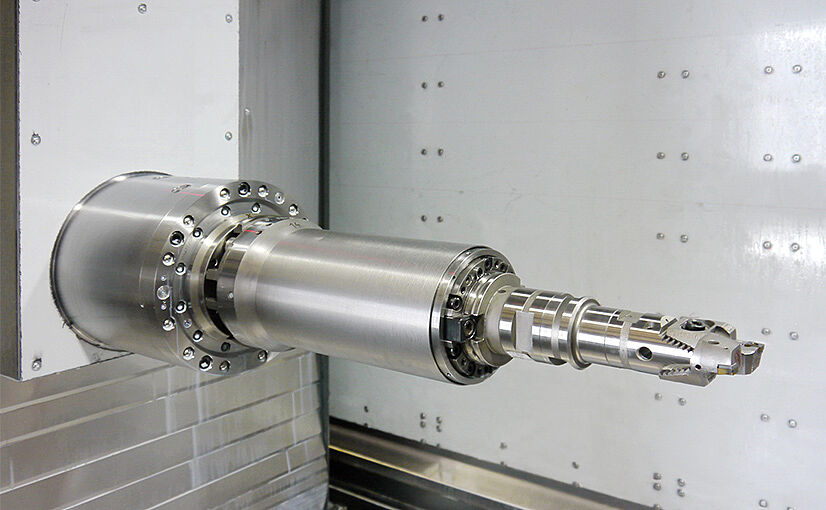

BW提供自己研发和制造的伸缩数控主轴,伸缩行程达1,000mm,下垂弯曲自动补偿功能。基于加工环境通过因瓦合金材料镶嵌条件下实现主轴长度自动补偿,具有很好的热稳定性。

BW提供自己研发和制造的伸缩数控主轴,伸缩行程达1,000mm,下垂弯曲自动补偿功能。基于加工环境通过因瓦合金材料镶嵌条件下实现主轴长度自动补偿,具有很好的热稳定性。

数控平旋盘具有滑动导向车削滑块和配重控制以减小不平衡量。BW自制平旋盘刀柄中心带控制轴通过高变速比来实现数控和车削滑块上车刀的µ级调整。

绝对集成式钻削附件头交换器用于存储多种特殊数控附件头,可进行多达30把刀具的自动交换。

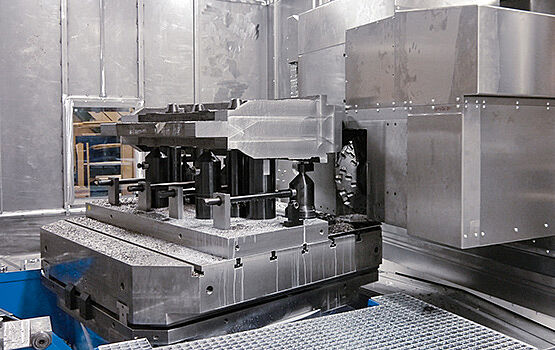

立式转台安装于机床转台上,具有极佳的排屑性能和良好的刀具通过性。转台表面结构自由配置,转台直径达2,000mm。

FLEXIBILITY – IN ALL DIMENSIONS

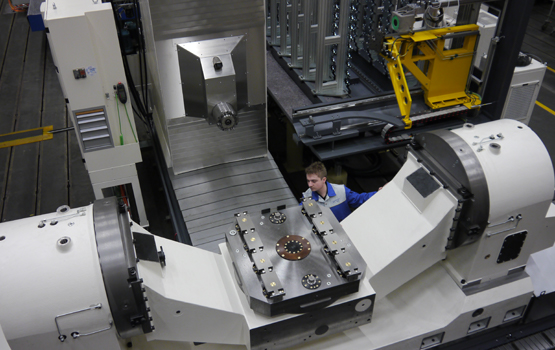

Almost all machine series of BURKHARDT+WEBER are available as 5-axis version including a HV-head, an A-axis (fork head) or a rotary/tilting table. The fields of application vary from aerospace industry to standard machine building as well as manufacturers of semiconductors and optical components. Gears up to a module of 9 can be produced with Power Skiving. Our solid and precise machining centers operate in single-item, small batch and serial part production.The A-axis is equipped with a motor spindle of 12.000 min-1 designed for particularly high speeds in continuous operation and optionally has a 4 point clamping for the adaption of turning tools.The spindle nose is pulled forward to avoid collision with the workpiece and to enable the machining of complex and diagonally arranged contours. In addition, the A-axis convinces with a high feed and clamping torque of the swivel axis. The fifth axis is applicable in different variations, either as continuous CNC-axis or as a plain positioning axis. The objective is to completely machine workpieces in a single clamping operation in order to meet the increasing demands for accuracy. Finally, this reduces the fixture costs and set-up times.

The BW custom-designed rotary/tilting table is always in action when the workpiece geometry makes is necessary.

The BURKHARDT+WEBER 5-axis multi-tasking machining centers enable a complete machining of workpieces with the technique of milling – turning – drilling.