ROLLER-GUIDED – MULTITASKING – SLIDE-GUIDED – ULTRA-PRECISE.

Complex, highly accurate components require machines with a high degree of process relevance to enable flexible and economical production. Machine tools from BURKHARDT+WEBER are designed in premium quality with high performance, tightest tolerances and an extremely sturdy construction. A wide variety of special equipment reduces your process times and increases flexibility with regard to component geometries.

Almost 140 years of experience in machine tool manufacturing and over 65 years of experience in building machining centers for sophisticated machining of steel and cast parts, in-house development and production of all key components by BW itself and highly skilled specialists yield the premium quality typical of BW.

ABSOLUTELY SOLID MACHINE ENGINEERING.

– is how customers describe BURKHARDT+WEBER. A seemingly simple assessment, but one that is as informative as it is multi-layered. Essentially it means one thing above all: sturdy design, use of the best materials, no compromises. BW machines are built for decades of production service in challenging conditions.

Based on the principle of “strong mechanical design instead of electronic compensation”, the machining centers are able to guarantee maximum accuracy and high output for many years, even with continuous machining of demanding materials. A BW can still perform as well after years of service as it does during commissioning.

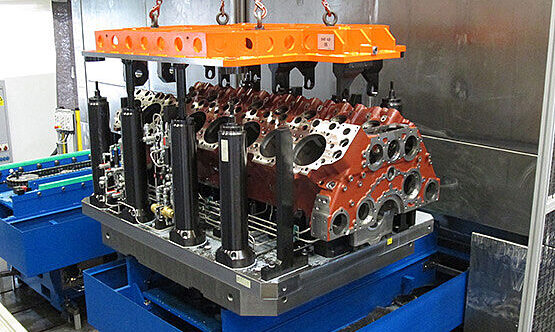

Machining of expansive and heavy workpieces necessitates a sound and well-conceived machine design. We have decades of experience with large machining centers and the associated machinery. BW working area ergonomics are trendsetting and the tool magazine is world-leading.

Absolutely solid machine engineering from the ground up. All assemblies are designed from the outset very solidly and for continuous operation.

Solid, heavily ribbed machine stands with high torsional stiffness.

ACCURACY IS INCREASINGLY IMPORTANT.

Combination of individual parts leads to increasingly complex geometries and fewer clamping operations. This significantly increases the demands on machining accuracy. BURKHARDT+WEBER manufactures its machines in a variety of precision classes to meet your specific requirements. High basic accuracy and consistent long-term accuracy that will last for many years, on that we stake our name: BURKHARDT+WEBER.

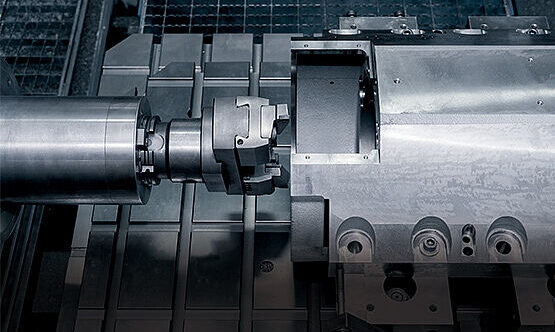

Cannot be achieved by machine: maximum flatness and parallelism of the guide supports are achieved only with handwork.

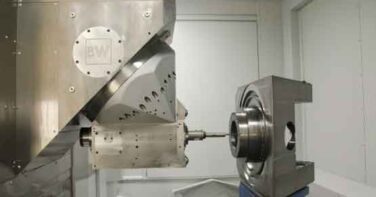

Tightly toleranced bore diameter, absolute concentricity with large bearing spacing and perfect angularity of faces.

AS INDIVIDUAL AS YOUR TASKS.

WHATEVER YOU WANT TO MACHINE, WE OFFER THE SOLUTION.

We have decades of experience in special-purpose machine building and implementation of turn-key projects as well as a highly capable process engineering team. The starting point for your individual machining center are your current and future process requirements.

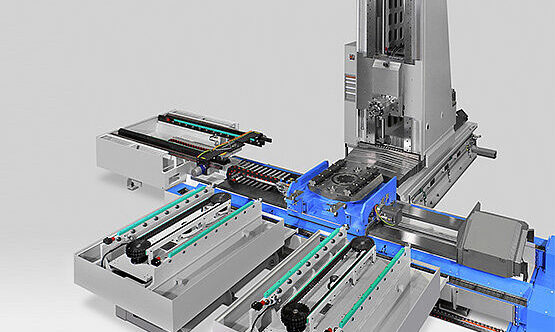

The machining of a wide range of materials in varying batch sizes demands highly flexible machining centers. We tailor your machining center to your needs from our different product ranges and an extensive assembly kit of additional equipment. Tool magazines with up to 800 tools, feeding of large and long special tools, workpiece automation, process monitoring and the associated clamping and production technology ensure efficient machining. With BW you benefit from our cost-effective modular design principle and the high level of individualized process relevance.

As much customization as necessary, as much standard equipment as possible.

Special-purpose machining centre with second spindle unit for gear cutting.

Complex hydraulic clamping device for a V16 crankcase, customer-specific and process-optimised.

HIGH-DEFINITION DIGITAL TECHNOLOGY.

Modern value chains rely on intelligent, digitally networked systems. At BURKHARDT+WEBER, Industry 4.0 means linking machining centers with cutting-edge information and communication technology. Not only can the BW machine be easily interlinked, but it is also ready for digital networking in self-organized production processes.

Integrated networked production brings many advantages, such as general efficiency improvement, the production of individual workpieces in series production quality, highly chaotic production or control of the tool magazine by the machine itself. Highly automated BW systems are completely integrated into our customers’ MES infrastructure.

The end-to-end digitization of the machines generate a significant additional benefit for process optimization. The systematic use of I/O-Link components enables all BW machines to document their entire life cycle via digital footprint and, supplemented by a digital fingerprint, allows conclusions to be drawn about the current machine condition.

With machining centers from BW you are ideally equipped to meet the digitalized future.

Smart Maintenance is BW's approach to helping you more effectively wherever you are in the world. For this purpose, BW now also uses mixed reality tools.

The real-time data processed and visualised on the machine by standard software applications enable the user to optimise processing, programming and maintenance of the machine and organisation of workpieces and tools.

YOUR EXPERIENCED PROJECT PARTNER.

You are expecting more from our strong and highly flexible machining centers and customized machines. Let our BW-Competence for developing and delivering complete solutions take the guess work out of getting the perfectly running, fully integrated machining system you want. Take control with our “RING OF POWER” – your complete, full featured path to success.