ROLLING MILLS AND MINING

Heavy machines for difficult tasks.

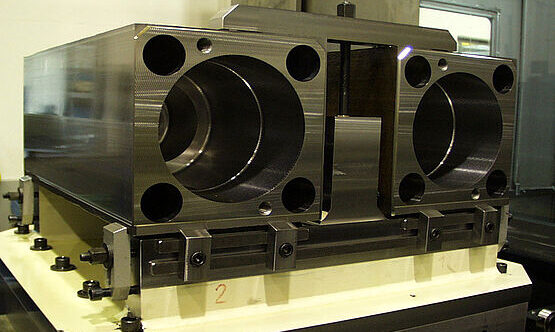

Framework, large welded constructions, booms, compact gearboxes, segment parts – up to 20 tons in weight are manufactured efficiently on customised BURKHARDT+WEBER machining centres. X-axes with up to 8,000 mm of travel, Y-axes up to 3,000 mm, quill spindle with 160 mm diameter and stroke of 1,000 mm, special magazines with special tools and individual weights of 300 kg, boring head changing equipment and the powerful BW tool magazine guarantee precise machining of your components.

All of our different machine series, such as MCX, MCR or MCT are suitable for any workpiece as we design your machine individually. The focus is on the component size and accuracy, which are the most important factors.

We have developed the compact MCC series for smaller components.

We supply more than just steel and iron. We want to be your holistic technology partner. You won’t find off-the-shelf machines with us. That is why we will select the best combination of product and machining technology based on our established modular system after a detailed technical analysis to meet your specific requirements.