PRINTING, PAPER AND PACKAGING

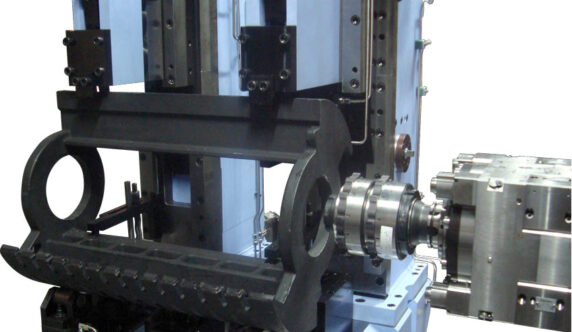

Maximum flatness for large components.

Whether it be side walls with the tightest of gauges and maximum flatness or expansive machine frames with multi-sided machining – the BW machining center is specially designed for your process. If extreme precision is required, then every BW machining center is also available in a high-precision version. Our experts hand-scrape the final microns, drives are cooled, and active component tempering is installed. Water and water coolers reduce the release of hot air to the immediate machine environment as required. Production at the highest technical level. What we are proud of: The µ is generated, not only compensated.

All of our different machine series, such as MCX, MCR or MCT are suitable for any workpiece as we design your machine individually. The focus is on the component size and accuracy, which are the most important factors and complex turnkey projects are not only our main expertise but also our great passion.

We have developed the compact MCC series for smaller components.

After a detailed technical analysis, we will select the best combination of product and machining technology based on our established modular system to meet your specific requirements.