PLASTICS AND WOOD

Pure production efficiency.

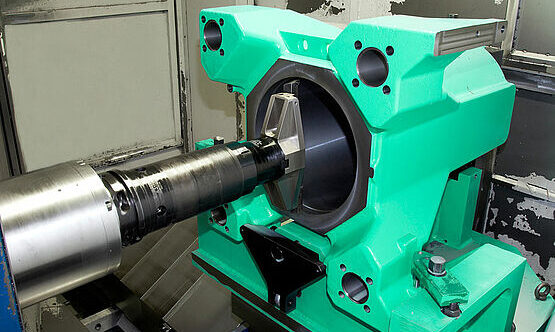

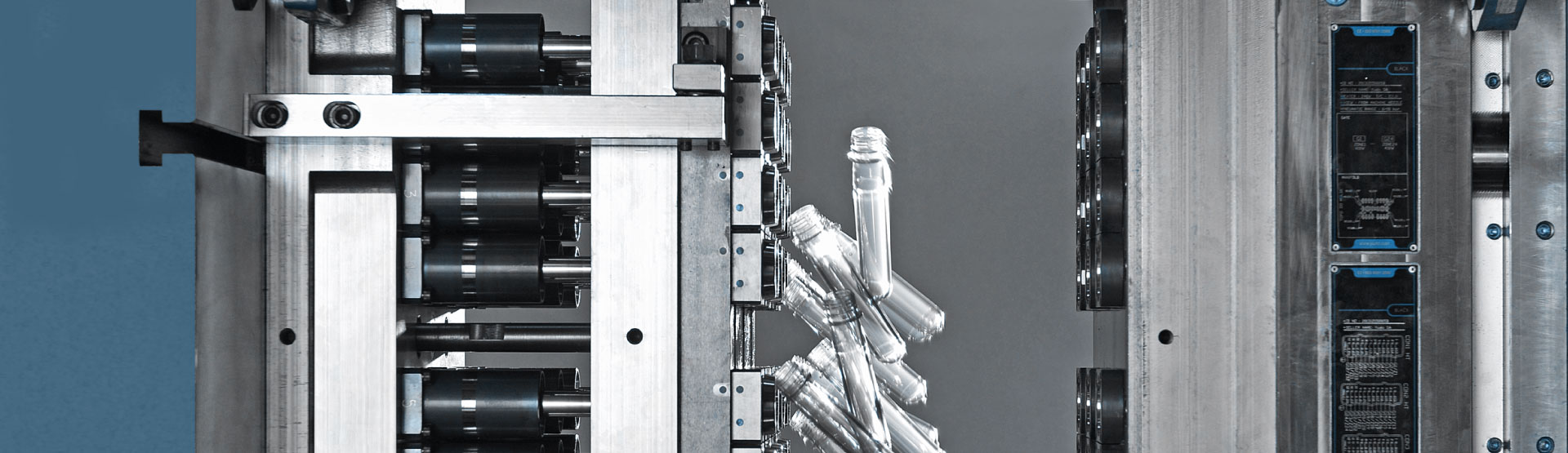

BURKHARDT+WEBER has many years of experience in machining components for plastic injection moulding machines such as base frames, cylinders, clamping plates, connecting rod drives and others up to 40 tons in weight. BW is at home with the exacting requirements for stay hole gauges and clamping plate flatness, deep boreholes and high cutting volumes. The generously dimensioned machining centers offer highest positioning accuracies and best angular positions, even in the case of large dimensions. High-performance pre-machining followed by fine machining is the speciality of BW.

All of our different machine series, such as MCX, MCR or MCT are suitable for any workpiece as we design your machine individually. The focus is on the component size and accuracy, which are the most important factors.

If it has to be very precise and ‘native precision’ is required, the MCµ is the right choice. For smaller components, we have developed the compact MCC series. Thus you can machine your entire workpiece portfolio on a real BW.

After a detailed technical analysis, we will select the best combination of product and machining technology based on our established modular system to meet your specific requirements.